HBS

HOLLOW BAR SYSTEM

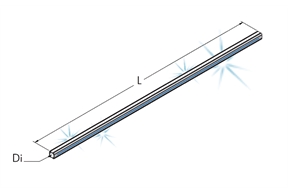

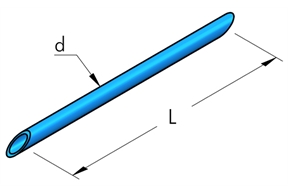

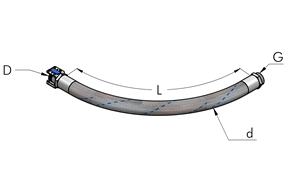

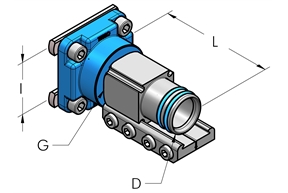

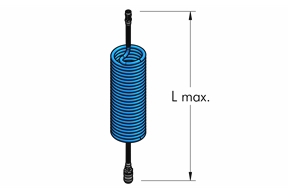

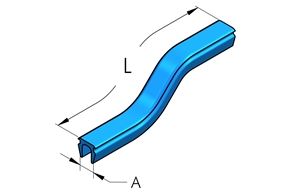

HBS - Hollow Bar System is the world’s first modular system made from extruded aluminium hollow bars, designed to enable the fast, safe, and functional installation of compressed air lines and other fluid distribution systems.

A milestone product in the sector, HBS remains unmatched to this day in terms of strength, efficiency, and versatility of application.

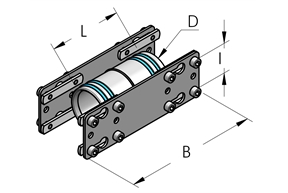

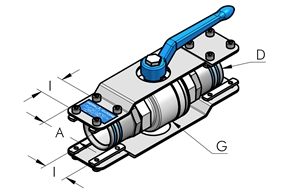

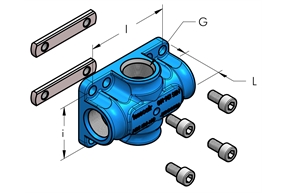

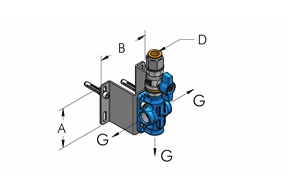

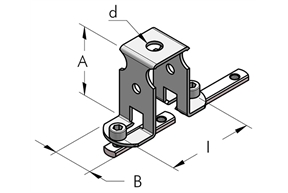

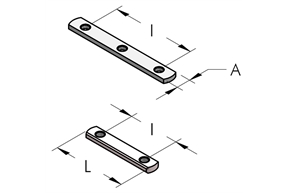

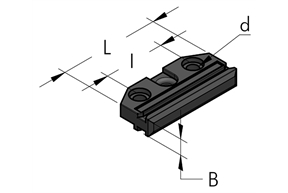

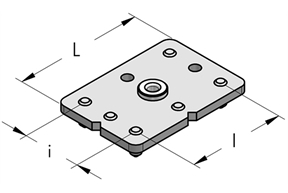

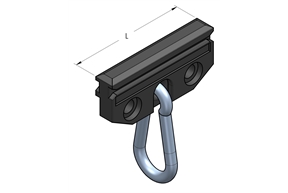

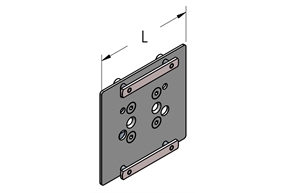

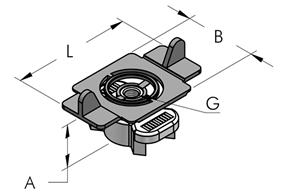

Thanks to its quick-fix outlet plates and blocks, the system can be easily and safely modified or extended at any time.

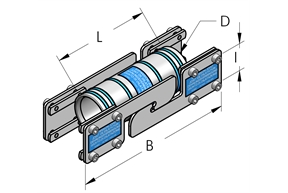

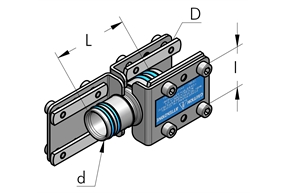

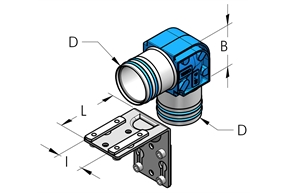

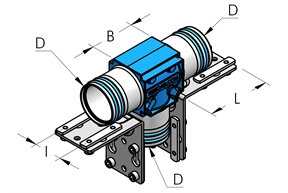

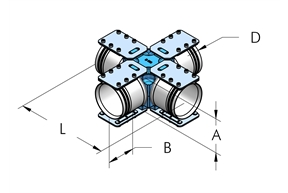

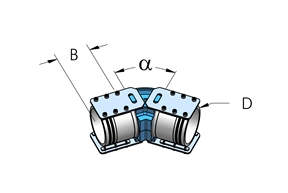

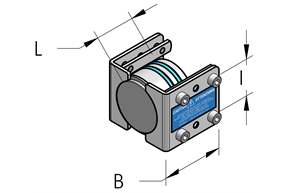

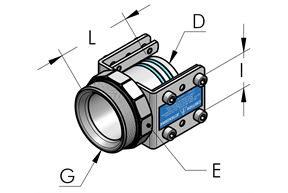

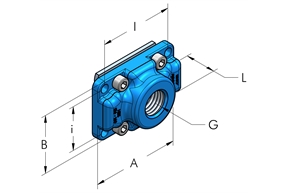

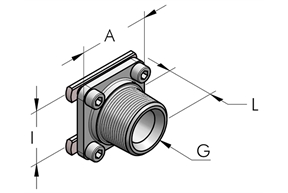

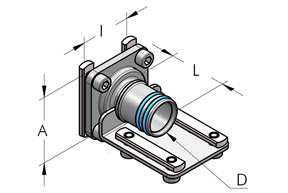

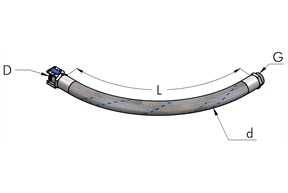

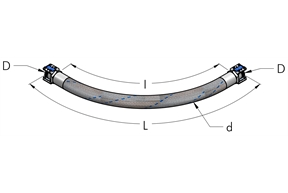

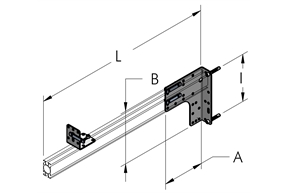

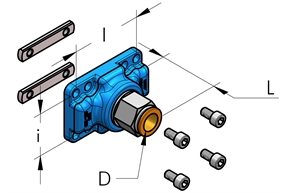

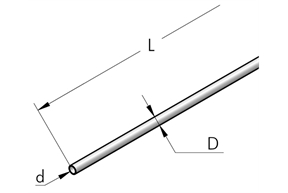

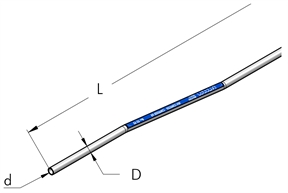

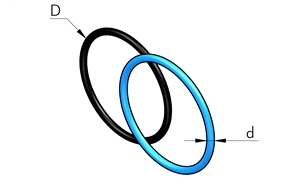

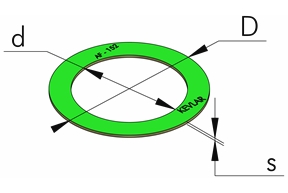

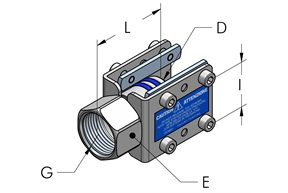

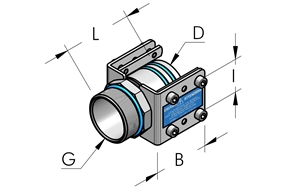

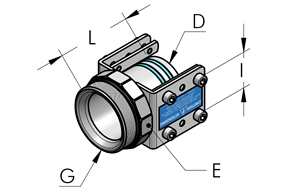

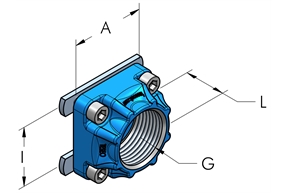

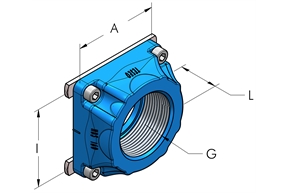

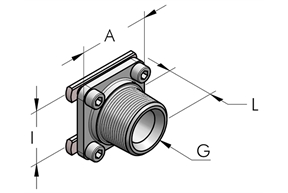

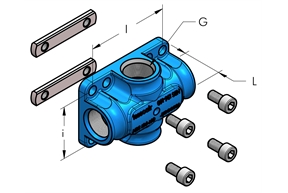

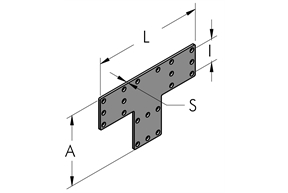

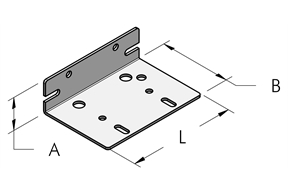

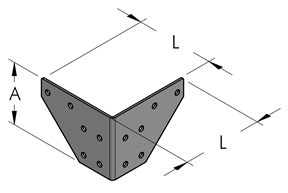

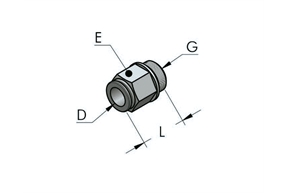

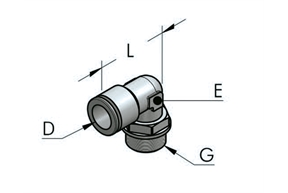

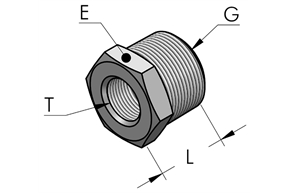

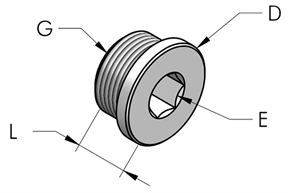

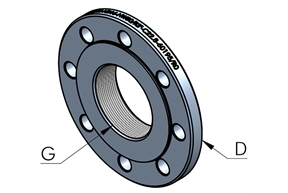

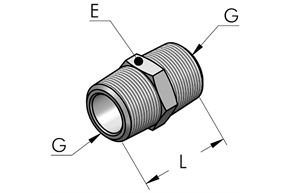

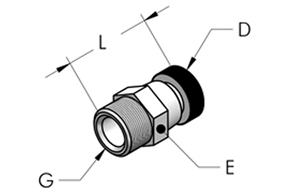

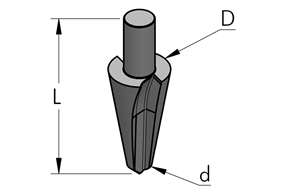

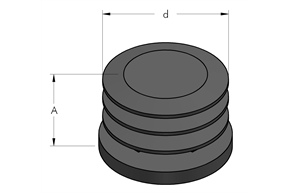

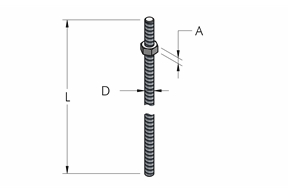

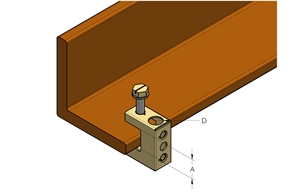

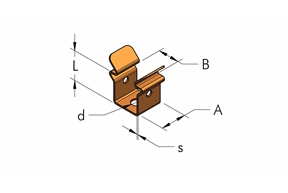

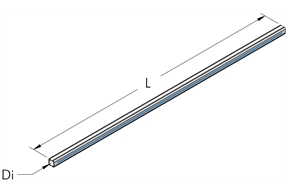

The system is based primarily on extruded aluminium hollow bars, available in various diameters. The bars are joined using straight, L and T connectors, sealed with O-rings to ensure tightness and reliability.

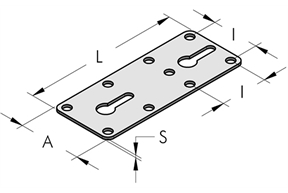

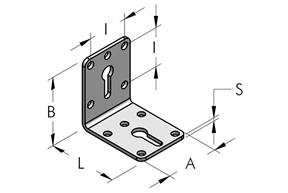

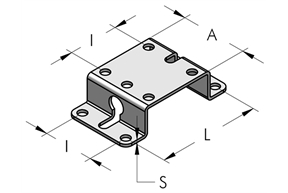

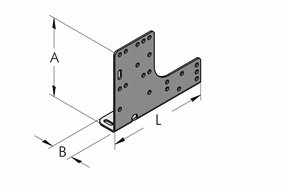

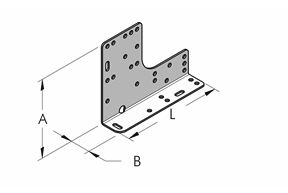

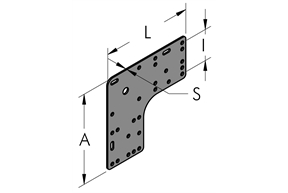

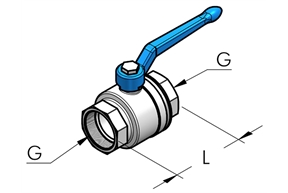

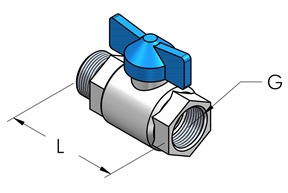

A wide range of outlet plates with ports from 1/8” to 2”, threaded ends in various sizes, accessories, and mounting brackets ensures maximum versatility for the system.

The following advantages stand out

- Fast installation;

- Easy to make changes and add new branch lines;

- Clean and smooth inner and outer surfaces;

- Integrated modular system;

- Energy efficiency;

- 100% recyclable aluminium.

Technical characteristics

- Extruded Aluminium: Alloy EN AW-6060 UNI EN 573-3:1996

- International designations: ANSI 6060 - DIN1748/1: AlMgSi 0,5 BS 6060

- Chemical composition: Si: 0,45 - Mg: 0,45 - Fe: 0,3

- Heat treatment: Aging T5 o T6

- Surface treatment (upon request) : Chemical silver anodization

- Specific weight, density: Kg/dm³ 2,71

- Electrical conductivity: % IACS 53

- Thermal Conductivity: W/m·K 200

- Specific heat: J/Kg·K 96

- Coefficient of expansion: mm/m °C 0,024

- Tensile strength: Kg/mm² 24

- Yield strength: Kg/mm² 20

- Modulus of elasticity: Kg/mm² 6.700

- Brinell hardness: HB 70÷80

- Melting range: °C 600-650

- O-ring material: NBR 70

- Operating temperature: °C -20/+120

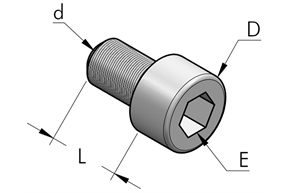

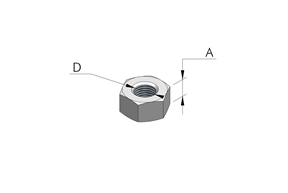

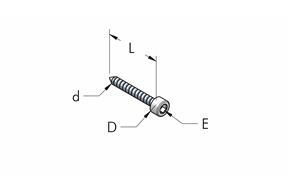

- Screw material : Steel class 8.8

- Screw driving torque: Nm 10÷13,5 (90÷120 Inch Lbs)

- Outlet thread: BSP or NPT

- Terminal thread: BSP or NPT

- Max operating pressure: 15 bar - 1,5 MPa - 217 psi

- Failure test pressure : 56 bar - 5,6 MPa - 813 psi

Compatibility with fluids

Compressed air, Vacuum,Argon, Nitrogen, Carbon dioxide, Mineral oil*,Synthetic oil*, Other fluids*.

*For further information, please apply to Teseo Srl Technical Office.

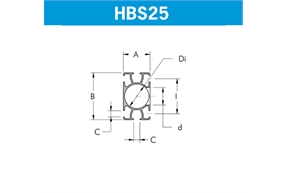

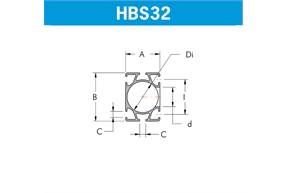

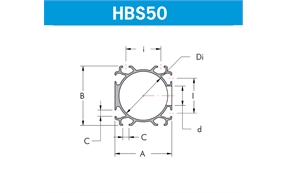

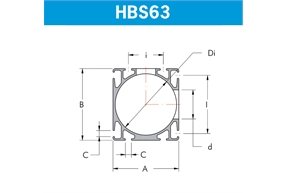

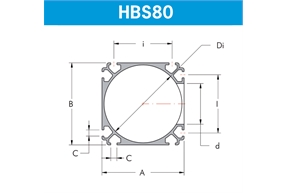

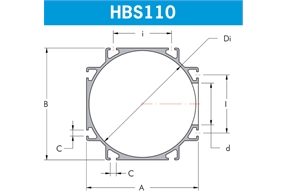

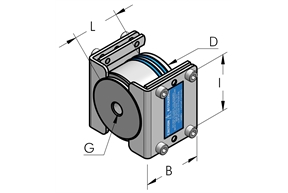

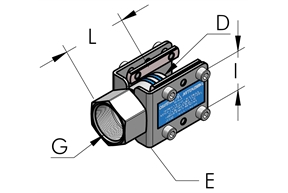

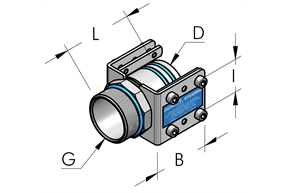

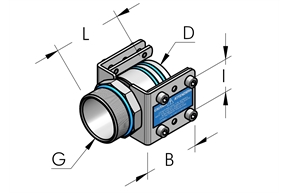

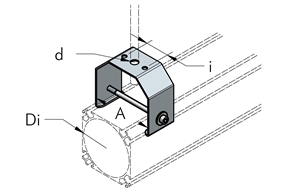

SECTIONS OF VARIOUS PROFILES

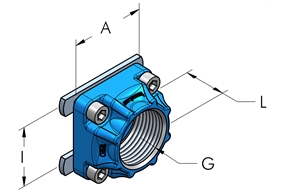

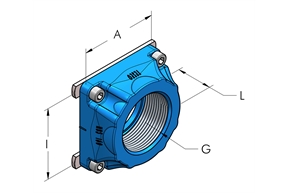

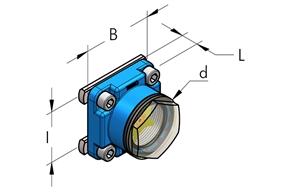

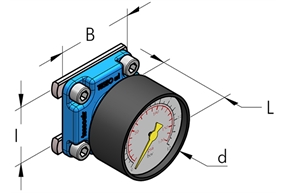

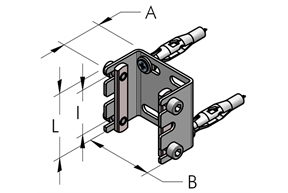

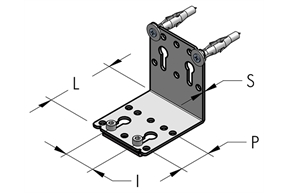

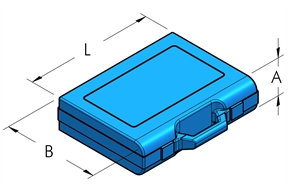

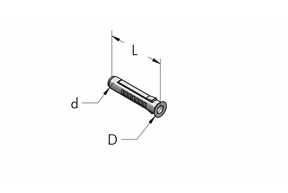

SIZE DIMENSIONS

| Di mm |

d mm |

I mm |

i mm |

A mm |

B mm |

C mm |

V l/m |

Jx cm4 |

Jy cm4 |

Sez cm2 |

P g |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HBS25 | 25 | 18 | - | 36 | 28 | 49 | 6.2 | 0.5 | 6.70 | 2.90 | 5 | 800 |

| HBS32 | 32 | 20 | - | 36 | 36 | 50 | 6.2 | 0.8 | 11.90 | 6.60 | 8 | 1150 |

| HBS50 | 50 | 20 | - | 36 | 60 | 60 | 6.2 | 2.0 | 25.00 | 31.50 | 20 | 1800 |

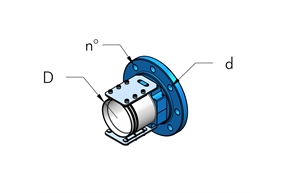

| HBS63 | 63 | 20/30 | 36 | 60 | 68 | 74 | 6.2 | 3.1 | 74.20 | 58.80 | 31 | 2770 |

| HBS80 | 80 | 42 | 60 | 60 | 85 | 85 | 6.2 | 5.0 | 120.00 | 120.00 | 50 | 3300 |

| HBS110 | 110 | 115 | 60 | 60 | 115 | 115 | 6.2 | 9.5 | 265.00 | 265.00 | 95 | 4200 |

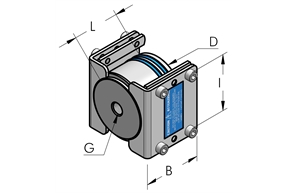

blue design

The new generation of the blue in TESEO is the result of the modification and the improvement of all the TESEO systems.

Our continuous R & D into Energy Saving together with a high regard for the Design ruled our technical choices. We studied the internal passages and the thicknesses to increase the flow rates through our tubing.

Double seats for the O-rings and high quality NBR Blue O-Rings, manufactured for Teseo, are applied to all the connections for high quality sealing.

Ergonomics of the complete system has been improved thanks to optimization of the shapes and weights. Precision manufacturing carried out on many components improves the outer finishing and removes the die-casting defects.

Outlet plates have been re-designed with new moulds, to improve quality and accuracy. The blocking parts have been analyzed and improved.

The implementation of accessories and components is continuous. Teseo are sourcing New certifications and international compatibility.