APS

ALUMINIUM PIPING SYSTEM

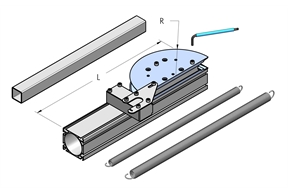

APS - Aluminium Piping System is TESEO’s aluminium piping line that expands the range of its modular pipework systems. APS is a patented solution developed by TESEO, the result of careful industrial design, engineering expertise, and years of hands-on experience in the installation of industrial systems. Thanks to its design excellence, APS received the IF Design Award for its ecological value.

The following advantages stand out

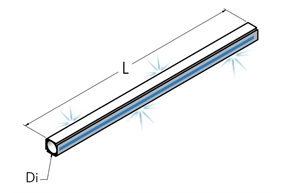

- Faster, quicker, and more intuitive assembly;

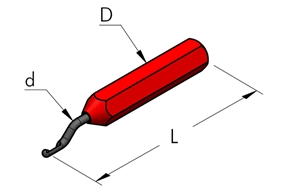

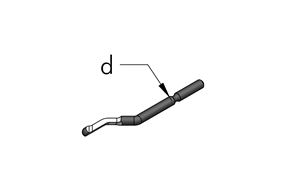

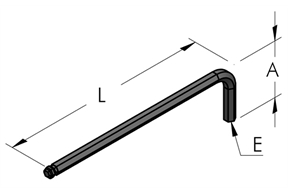

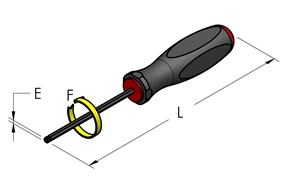

- No need for special or expensive tools;

- Easy to install, allowing even less experienced users to complete the assembly successfully, provided they have first read the instruction manual;

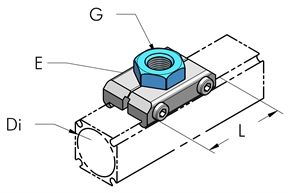

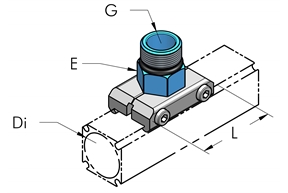

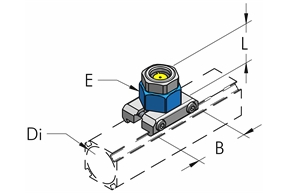

- Symmetrical profile;

- All four faces can be used;

- Easy to cut;

- Wide range of accessories, compatible with TESEO HBS line and with both BSPP/BSPT (“GAS”) and NPT threaded pipes;

- Competitive and cost-effective compared to traditional systems on the market, thanks to its design, system technology, and fast assembly – with no waste;

- 100% recyclable aluminium and reusable components, supporting a true circular economy.

Technical characteristics

- Extruded Aluminium: Alloy EN AW 6060 UNI EN 573-3:1996

- International designations: ANSI 6060 - DIN 1748/1: AlmNsl 0,5 BS 6060

- Chemical composition: Si: 0,45% - Mg: 0,45% - Fe: 0,3%

- Heat treatment: Aging T5 o T6

- Surface treatment (upon request) : Chemical silver anodization

- Specific weight, density: Kg/dm3 2,71

- Electrical conductivity: % IACS 53

- Thermal Conductivity: W/m.K 200

- Specific heat: J/Kg.K 96

- Coefficient of expansion: mm/m °C 0,024

- Tensile strength: Kg/mm2 24

- Yield strength: Kg/mm2 20

- Modulus of elasticity: Kg/mm2 6.700

- Brinell hardness: HB 70÷80

- Melting range: °C 600-650

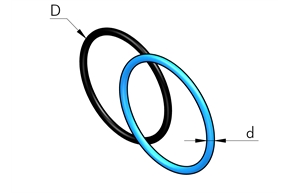

- O-ring material: NBR 70

- Operating temperature: °C -20/+120

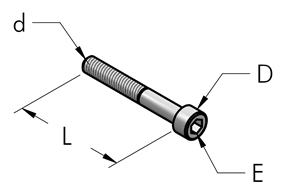

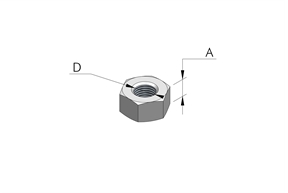

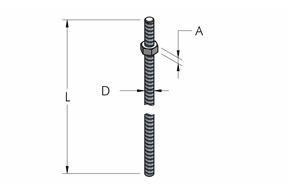

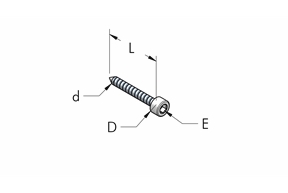

- Screw material: Steel Class 8.8

- M5 Screw driving torque: 10 N·m (90 Inch·Lbs) ± 10%

- M6 Screw driving torque: 14 N·m (120 Inch·Lbs) ± 10%

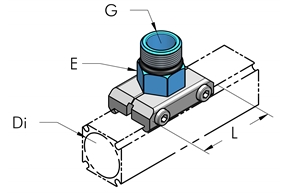

- Outlet thread: BSP or NPT

- Terminal thread: BSP or NPT

- Max operating pressure: 15 bar - 1,5 MPa - 217 psi

- Failure test pressure: 80 bar - 8 MPa - 1160 psi

Compatibility with fluids

Compressed air, Vacuum,Argon, Nitrogen, Carbon dioxide, Mineral oil*,Synthetic oil*, Other fluids*.

*For further information, please apply to Teseo Srl Technical Office.

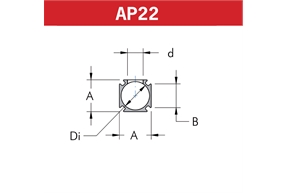

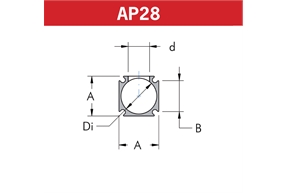

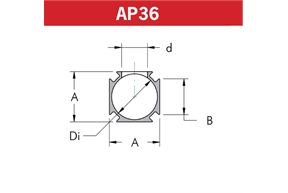

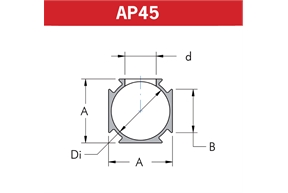

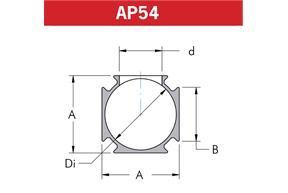

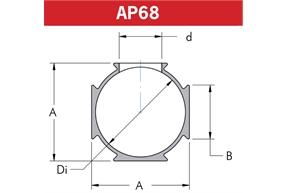

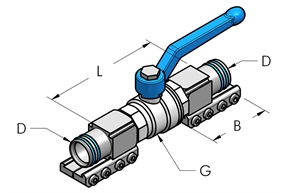

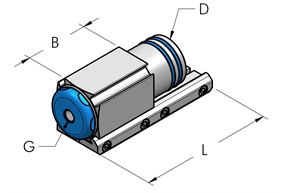

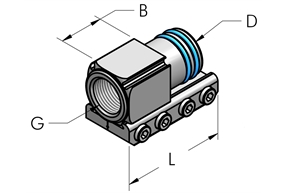

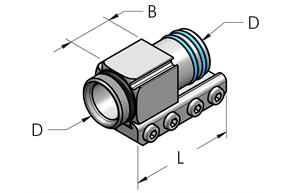

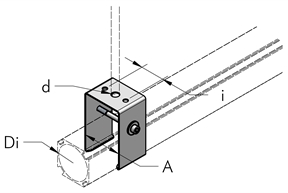

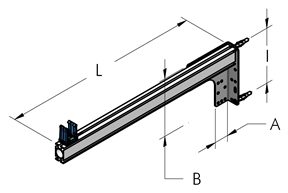

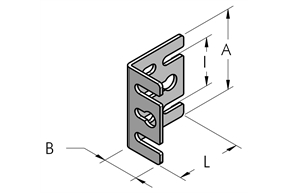

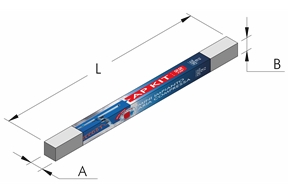

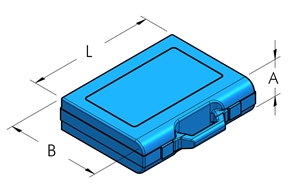

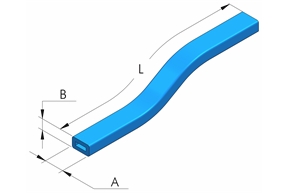

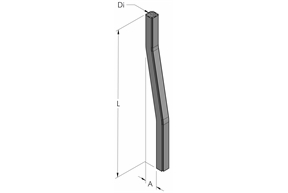

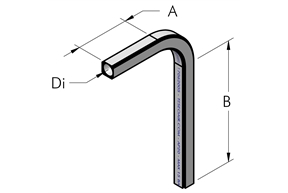

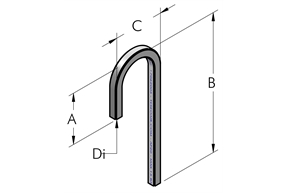

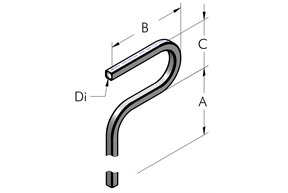

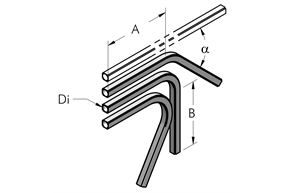

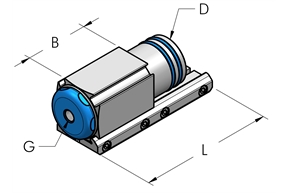

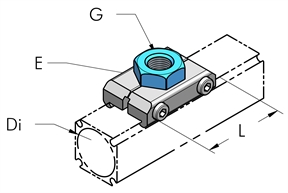

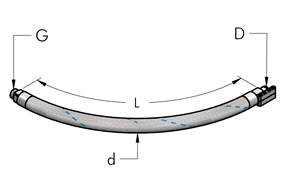

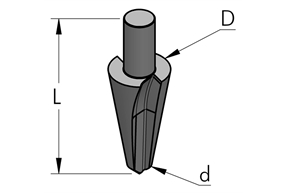

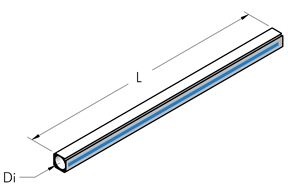

SECTIONS OF VARIOUS PROFILES

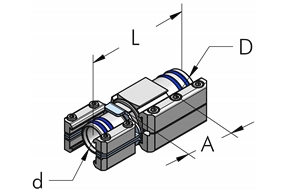

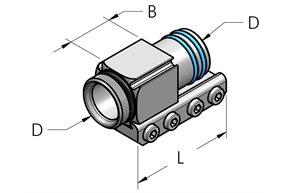

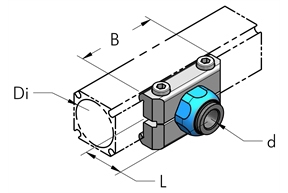

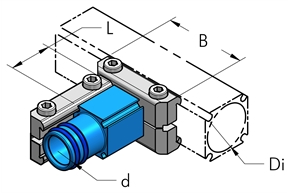

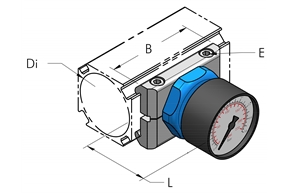

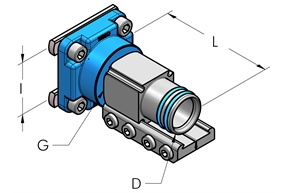

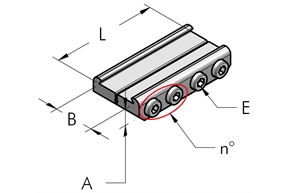

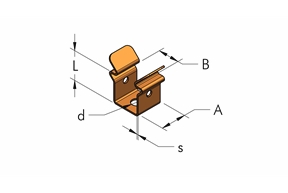

SIZE DIMENSIONS

| Di mm |

d mm |

A mm |

B mm |

V l/m |

Jx cm4 |

Jy cm4 |

P g |

|

|---|---|---|---|---|---|---|---|---|

| AP22 | 20 | 11 | 22.4 | 16.4 | 0.32 | 0.90 | 0.90 | 370 |

| AP28 | 25 | 15 | 28 | 21.5 | 0.5 | 2.20 | 2.20 | 590 |

| AP36 | 32 | 18 | 36 | 25 | 0,8 | 4,60 | 4,60 | 780 |

| AP45 | 40 | 22 | 45 | 31 | 1.3 | 11.00 | 11.00 | 1170 |

| AP54 | 50 | 30 | 55 | 38 | 2 | 23.70 | 23.70 | 1690 |

| AP68 | 63 | 30 | 69 | 38 | 3.1 | 44.10 | 44.10 | 2080 |

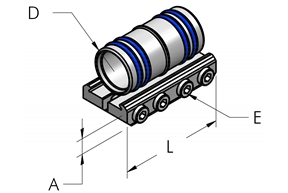

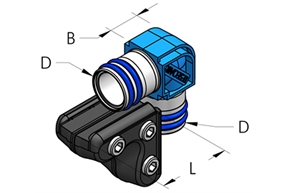

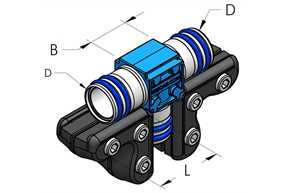

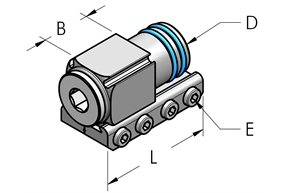

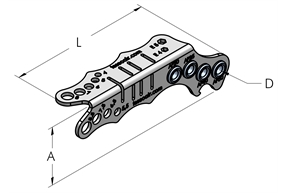

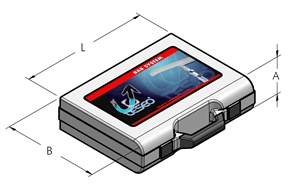

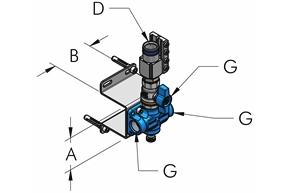

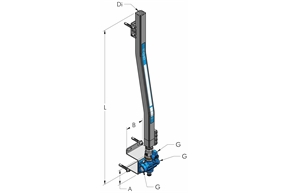

blue design

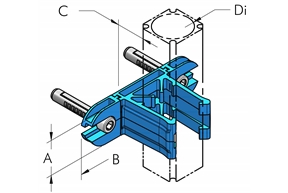

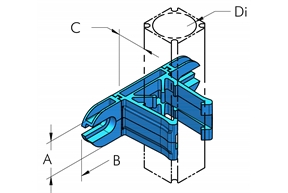

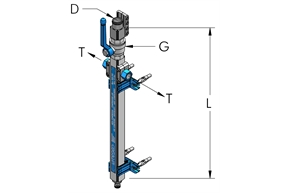

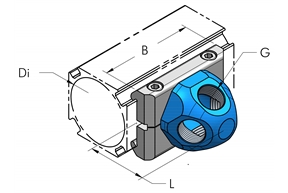

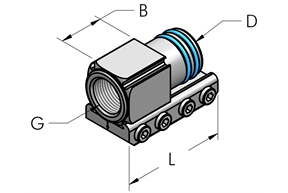

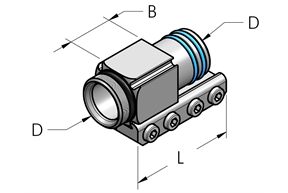

The new generation of “blue” in TESEO is the result of the modification and the improvement of all the Teseo systems. Our continuous research into Energy Saving together with a high regard for the Design ruled our technical choices. We studied the internal passages and the thicknesses to increase the flow rate.

Double seats for the O-rings and high quality NBR Blue O-Rings, manufactured for Teseo, are applied to all the connections for a better sealing.

Ergonomics of the complete system has been improved thanks to optimization of the shapes and weights. Precision manufacturing carried out on many components improves the outer finishing and removes the die-casting defects.

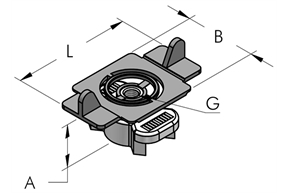

Outlet plates plates have been re designed with new moulds, to improve quality and accuracy. The blocking parts have been analyzed and improved.

The implementation of accessories and components is continuous.

Teseo are sourcing New certifications and international confirmation.